Sign up for Essential California

The most important California stories and recommendations in your inbox every morning.

You may occasionally receive promotional content from the Los Angeles Times.

A freight train passes through Birmingham, Ala. Some of its chassis are empty amid the supply chain crunch.

The great American supply chain has hit the skids. Once a marvel of logistics that hummed with scheduling rigor and pricing predictability, the fount of goods has slowed to a trickle as key supply links have broken down in recent months.

Cargo ships idle off the coast of Southern California, freight trains carry empty cars, and trucking companies struggle with labor shortages.

In late October, I had an opportunity to get a firsthand look at the economic mayhem. I had recently accepted a reporting position with The Los Angeles Times, which required a timely cross-country trip. I left Birmingham, Ala., where I had lived for six years, and headed to California in a 16-foot moving truck packed with my family’s belongings, making detours through communities large and small along the way.

What I found was a series of startling illustrations of the fragility of the supply chain and the many ways businesses across the southern U.S. are affected when the flow of goods clots at the ports of Los Angeles and Long Beach.

In all, I interviewed nearly three-dozen people on my 2,668-mile journey — from Main Street retailers to big box outlet clerks, manufacturing executives to working artists — and the overwhelming majority of them had a supply chain tale of woe to tell.

Follow a container of board games from China to St. Louis to see all the delays it encounters along the way.

Erick Forsyth stokes the fire in his forge at The Three Graces Studio in Birmingham, Ala. (Connor Sheets / Los Angeles Times)

For generations after industrialists began digging iron ore, coal and lime out of the low mountains of north-central Alabama in the 1870s, Birmingham was a steel town, with fiery furnaces belching thick smoke that darkened the sky.

Blacksmith artist Erick Forsyth is a throwback to that bygone era. A force over the forge at his downtown workspace, The Three Graces Studio, he is a one-man metalworking operation.

He mends damaged statues, builds railings for house-flippers, and travels to competitions in Europe to create metal sculptures inspired by great philosophers and ancient myths. On Oct. 21, the day before I left for California, I watched Forsyth shape a hunk of molten iron into a serpentine form, creating art from the rawest of material.

That morning, as he held a cast-iron rosette in his hand, Forsyth said he waited five months for a shipment of the decorative, rose-shaped pieces to arrive earlier this year before he decided to make them himself. That required many hours of extra labor and cost $13 more per rosette, but he said he had no other option.

“I couldn’t pass all that on to the consumer, so I lost money on that job,” he said, adding that it wasn’t a one-off issue. “I had containers sitting in the dock in California for three months this spring.”

Just before lunch, I went with Forsyth to the Lawler Foundry, a local metal distributor on Birmingham’s east side. He’s there so often picking up supplies that the warehouse workers and office staff all know his name. But lately, even basic supplies like satin black paint have been hard for the company to come by. Customers like Forsyth regularly wait as long as two months for orders that previously took one or two weeks, said Melissa Hancock, a sales representative at Lawler.

“We have multiple containers held up there in L.A.,” she said. “It impacts our business dramatically.”

Best-known as the site of one of the longest and most brutal sieges of the Civil War, today Vicksburg is largely a tourist destination where tour buses and cruise ships carry war buffs and gamblers to its national battlefield and casinos along the Mississippi River. But the town is still home to over 20,000 people, and when they pass away, they are often interred at the 67-year-old Greenlawn Gardens Cemetery.

Sprawled across more than a dozen grassy acres on the outskirts of Vicksburg, the cemetery has been owned by the Sharp family since 2011, when David Sharp’s father purchased it from its prior owner. The outfit had little trouble sourcing materials over the nine ensuing years, but in recent months, Sharp said, the supply chain crisis has reached even this small-town resting ground.

“I made this big granite order back in June and she said it would be two to three months. I said, ‘OK, I understand.’ It normally takes about 1½ months, but she said she was having trouble and they had nothing in stock,” he said. “But, end of September, beginning of October, I called her again and said, ‘Look, where are we?’ and she said, ‘We’re at about five to eight months now.’”

Meanwhile, funerals have continued, but for the first time since the Sharps took ownership of the property, the cemetery has had to install cement headstones as place markers while granite remains on backorder.

Sharp, a former high school history teacher, said he’s been told the ongoing labor shortage in the trucking industry is a key driver of the long delays he’s had sourcing granite and bronze. When I spoke with him on Oct. 22, he said that he had to inform a local family earlier that day that a bronze scroll slated to be installed on a relative’s headstone was delayed and that he did not know when it would arrive.

“You have these families that are grieving the loss of their loved ones and I have to give them more bad news, which is that we can’t fully install the memorial because we can’t get the materials,” he said. “That’s the burden that we’re having.”

As in many small Texas communities, life in Carthage centers around a town square where locally owned businesses still populate most of the storefronts. Truck drivers carrying lumber and feed pass through the square en route to nearby Marshall or Nacogdoches, stopping off for a burger at the Texas Tea Room or a quick trim at a barbershop called “Jesus Shaves.”

Kelly and Scott Reeves own an old-fashioned soda fountain on the square in Carthage called Sunflower Mercantile. Much of their business is in the Blue Bell ice cream and sandwiches they serve to locals and passers-through, but recently they’ve had more trouble with their gift shop.

“We ordered a lot of stuff for Christmas season, which is one of our big seasons, and it never came in,” Scott Reeves told me on Oct. 23. “I called and the reps can’t tell you when it’s coming either. It’s all stuck in transit, a lot from Asia — China, Vietnam — so we had to cancel a lot of orders.”

Most concerning, Scott Reeves said, is the fact that “it doesn’t seem to be getting better.” A Vietnamese manufacturer told him on Oct. 22 that it didn’t know when he should expect delivery of toys he ordered months ago. Another company that offered free shipping in past years recently charged the store $500 to deliver less than $2,000 of merchandise.

“The shipping is killing us and we don’t want to raise prices, but unfortunately we’re probably going to have to,” Scott Reeves said.

A short walk away, Jeremy Cain described similar shortages. He manages the family business, Cain True Value Hardware, and said he’s having trouble getting everything from HardiBacker cement board to certain types of paint.

“The most common primer, we gotta wait ‘til December for,” Cain said. “We finally got some PVC pipe and it’s $130 for a 24-foot piece. Used to be about 40-something dollars.”

Though many of the economic issues driving today’s supply chain crunch first emerged while Donald Trump was president and were exacerbated by the pandemic, the current administration gets most of the blame in heavily conservative parts of the country like Panola County, Texas — home to Carthage — where Trump received more than four times as many votes as Joe Biden did in the 2020 election.

Nick John, a yard hand and delivery driver for Cain Hardware, blames the price increases and shipping delays on “inflation and politics,” and Cain chimed in to add “and this current president.” But sales at his shop have increased in recent months, which Cain chalked up to fears of runaway inflation and widespread concern in east Texas over the way the economy is headed under Biden.

“People are stocking up because people think it’s going to get worse before it gets better,” he said.

President Biden could face political blowback from unhappy shoppers as he struggles to fix supply chain problems.

Nestled at the foot of the Franklin Mountains northwest of the border where El Paso, Texas, meets Ciudad Juarez, Santa Teresa is a burgeoning industrial hub with deep connections to its neighbors to the south.

Growing up in Juarez, Miriam Baca Kotkowski says she remembers the moment, playing with Tonka trucks with her older brother, when she knew she wanted to own a real tractor trailer.

In 1998, her childhood dream came true when she founded Omega Trucking in Santa Teresa with five trucks and a loan from a friend. By January 2021, when the company was acquired by El Paso-based TECMA Group, Omega had 24 tractor trailers and 26 drivers hauling materials and goods both within and between the U.S. and Mexico.

Now president of TECMA Transportation Services in Santa Teresa, Kotkowski says she has weathered difficulties in the trucking industry before, but none quite like the price volatility caused by the current supply chain crisis. Last month, for example, a customer having trouble getting cargo from the Port of Los Angeles asked TECMA to transport the goods in its trucks. Kotkowski drew up a quote, noting that the cost would likely change within a month.

“I can’t imagine how that (cost) will be passed on to customers,” she said. “Like, ‘Oh, these dolls are $20 this week, and next week they’re $30?’”

The supply chain crunch has had broad implications for TECMA Group’s manufacturing and transportation business, according to Porfirio Waters, president of TECMA Customs Solutions. Lately, Waters said, truck drivers often arrive at the ports of Los Angeles and Long Beach at the scheduled pickup time only to learn the cargo container isn’t ready to go.

“That’s added cost for labor, diesel, time,” Waters said. “All that gets passed on to the customers who are screaming that they need their cargo. But it’s not available.”

A global supply chain breakdown has resulted in gridlock at the ports of Los Angeles and Long Beach and beyond.

Though Route 66 no longer runs all the way from Chicago to Santa Monica, long stretches of the historic throughway and its roadside attractions and mom-and-pop stores have been preserved just off I-40. But there also have been many changes along Route 66, and today a shopping center with an Old Navy store stands near the point where it intersects with Highway 89 in Flagstaff.

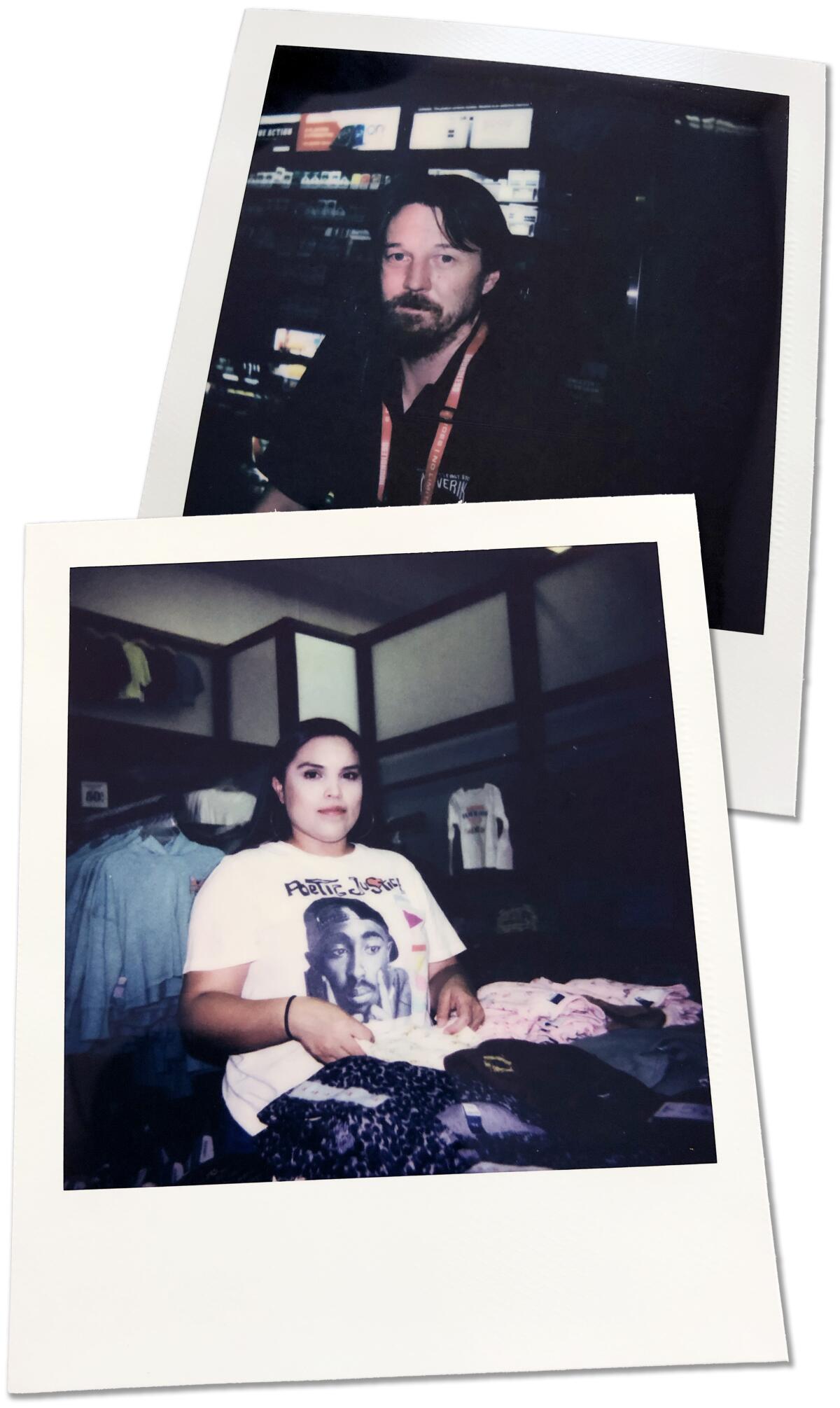

Maritza Ramirez, the store’s assistant general manager, told me that shipments of products and supplies that used to take a week to arrive are now often held up for two months or longer. Items in short supply include clothing, accessories and latex gloves.

“We don’t get certain items anymore in the store. Like, we stopped getting men’s shoes entirely in August,” Ramirez told me as she folded clothes on Oct. 28. “Our toilet paper, our cleaning supplies, all that stuff is taking a long time. We have had to go to the grocery store to get toilet paper.”

About a mile north, Tim Hale, operations manager for a Maverik gas station on Highway 89 in Flagstaff, said the supply chain crisis has left him with an ever-changing list of unavailable items. Taking a break from manning the cash register, he said that one of his biggest headaches is cups. He’s got plenty of Coke and Pepsi, but he can’t sell fountain drinks without cups.

“Cups are one of the biggest issues. It’s a new thing, they’ve been really hard to get,” Hale said. “And when they do come in, they’re just blank because [manufacturers are] just cranking them out and don’t have the time to print anything on them.”

The round space that usually holds XXL-size cups has been closed off with clear tape for months.

David Jauregui was out of a job in 2016 when he decided to sell some of his belongings for quick cash. Among the items were several pieces of wooden patio furniture that he had built. When they sold for hundreds of dollars, he realized he had the makings of a business.

So he started building tables and shelves, first in his backyard and then in his garage, eventually bringing on his cousin, Fabian Guzman, another partner, and two employees. Last year, the company, called Ocean Beach Pallet Co., moved into a workshop near the Port of San Diego, where Jauregui and crew specialize in handcrafted shelving for vinyl record albums, sold via their website and Etsy page.

The sawdust-caked space is little more than a couple of brightly lit rooms buzzing with the sound of power tools, but business boomed during the pandemic, as people looked to spruce up their living spaces.

Then the supply chain crunch hit. This year, Guzman said, shipping and lumber costs have skyrocketed, and inventory of many sealants and stains has dried up at Home Depot and other nearby retailers.

“We drive as far out as 50 to 80 miles or we turn to eBay or Amazon for a color. Or, as a last resort, we try to attempt to mix a color ourselves, which is not an exact science at all,” Guzman said, adding that he snaps up supplies when they’re available. “Now that we’re aware of the constraints, we keep a large inventory.”

After nine days on the road, I arrived at my family’s new apartment in Torrance on Oct. 30, unloaded the truck, and quickly encountered my own supply chain hiccup. Back in Alabama, we had to leave our beloved gray-blue couch behind. Getting a new one became an exercise in frustration.

We test-sat dozens of loveseats and sofas in furniture showrooms across the South Bay, from the Carson IKEA to Living Spaces in Redondo Beach. Several fit the bill, but whenever we checked the tag or talked to a sales rep, the answer was always the same: “currently unavailable.”

We ended up doing something we’d sworn we’d never do: We ordered a couch online, sight unseen and seat un-sat. These days the kids watch “Frozen 2” on folding chairs and my wife and I squint through episodes of “Succession” on the laptop in bed.

But at least the new couch is on its way. It’s due to arrive by Dec. 2, supply chain willing.

A hazy fog that stubbornly refused to burn away puzzled residents across the region last weekend. The experts make sense of it.

Sign up for Essential California

The most important California stories and recommendations in your inbox every morning.

You may occasionally receive promotional content from the Los Angeles Times.