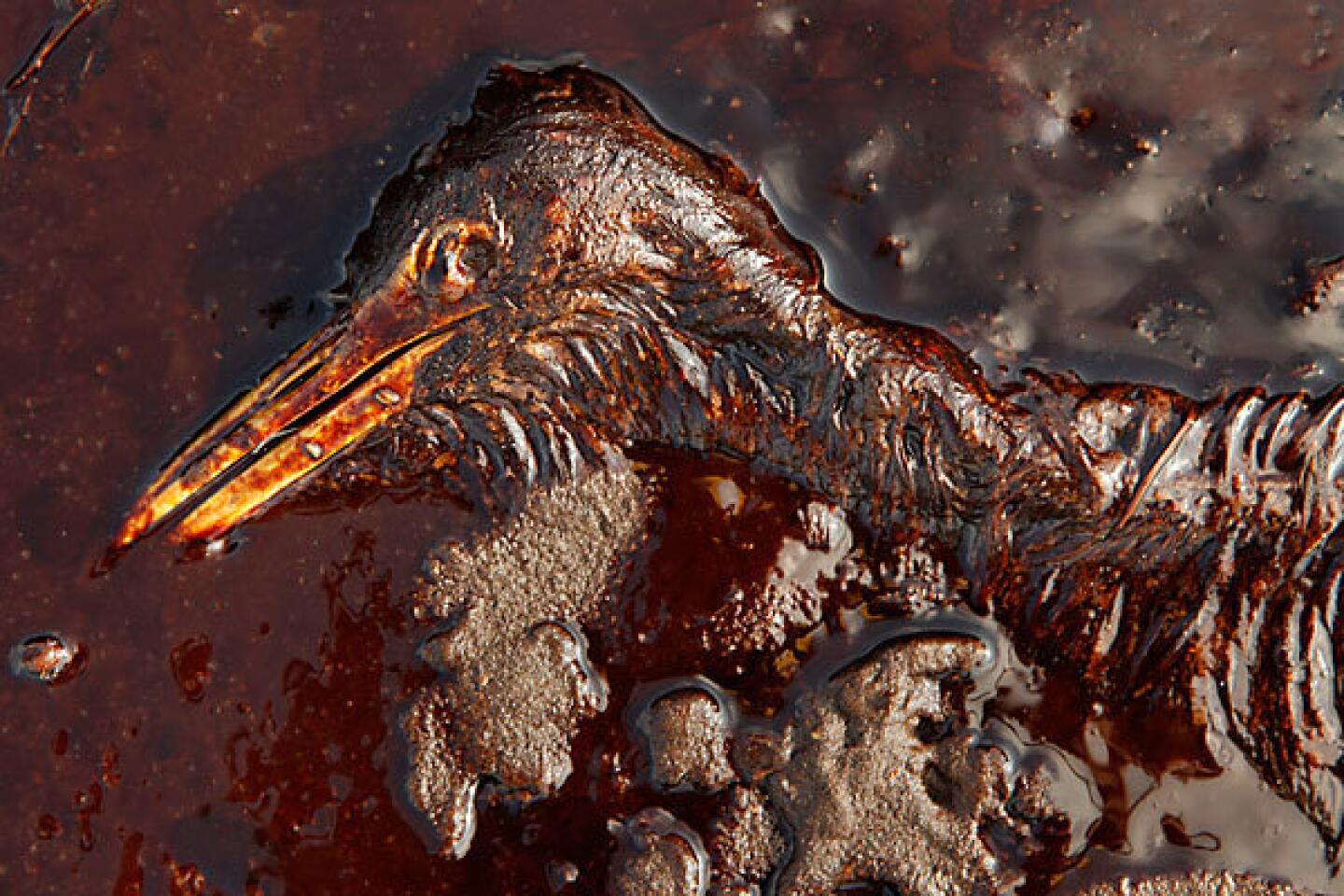

Oil spill caused by ‘a confluence of unfortunate events’

Flaws in a cement encasement intended to seal BP’s well were most likely the root of last month’s deadly explosion on the Deepwater Horizon drilling rig, according to interviews, government officials, congressional hearing testimony, drilling reports and other company documents.

The April 20 accident, which has resulted in millions of gallons of oil being spewed into the Gulf of Mexico, is the subject of multiple investigations that promise to be long and complex. Hearings in the last two weeks offered multiple lines of inquiry into what one engineer calls “a confluence of unfortunate events.”

But at least a dozen experts with intimate knowledge of offshore drilling, including one who has seen investigation documents, agreed that, deep in the well, cement, or pipes encased by cement, had to have failed first.

Several have specifically fingered BP’s design for that cement job, which used relatively little cement and relied on an unusual configuration that made it harder to test for imperfections, they said.

Cementing is supposed to form an impenetrable seal to keep the hot, gassy oil from surging up the well. But a single flaw in that seal, perhaps a crack the size of a human hair, can be enough to unleash a volcano of petroleum.

The Mississippi Canyon Block 252 project had encountered problems, including two reported gas kicks, where drillers failed to keep gas from surging up, according to the hearings and company sources. Government and company documents suggest the project was over budget. But the Deepwater Horizon had struck oil, something that happens in only about a quarter of exploration wells.

All that was left to do was to seal the well so another vessel could produce from it later. Cementing involves standard techniques. But “there is an art to it, and every well is a little different,” said Gene Beck, an associate professor of petroleum engineering at Texas A&M who testified at the congressional hearings.

Halliburton, the cementing contractor, worked according to BP’s design.

An exploratory oil well consists of a series of nested pipes, or casings, each plunging deeper into the seafloor. Crews pumped cement into the well until it crept outside of the steel casings, forming a bond between the pipe and the rock deep under the seafloor.

The goal was to let the cement set, add a few temporary cement plugs within the casings for good measure, then haul up the blowout preventer and move off.

But forming a good seal is tricky. Traces of drilling mud, a clay substance used to tamp rising oil as crews work, can pollute wet cement, creating weak spots. Wet cement also can drizzle into the rock or be distributed unevenly, leaving gaps — especially if the casings aren’t properly centered in the well — which can cause the encased pipes to collapse.

Any of these failures can give gas under extreme pressure a chance to creep in and build up in the well bore, or between nested casings.

Beck said BP’s encasement design called for only partial coverage of casings deep in the well. Cement did not reach the bottom of the next-largest casing in high-pressure areas, a decision Beck called “shocking.” He also raised questions about the design’s reliance on a single, central casing instead of several for the 2.5-mile-deep well. For technical reasons, BP’s configuration would make it more difficult later to test the cement job for leaks.

Several other independent engineers agreed with Beck’s assessment, although they said more information was needed. Alfred Eustes, associate professor of petroleum engineering at the Colorado School of Mines, cautioned that conditions particular to the formation could have dictated the design. BP declined to comment on this and other issues raised in this article.

The crew of the Deepwater Horizon conducted pressure tests that assess seals, but not the cement.

Hearing testimony suggested that the pressure tests revealed some discrepancy. It could have been a confusing, anomalous reading that meant little. Or it might have provided an early hint that gas had begun to leak into the well bore, perhaps creeping up through the mud between the casings, said Tadeusz Patzek, professor of petroleum engineering at the University of Texas in Austin.

An official with Transocean, the company that leased the drilling rig to BP, has cited “hearsay” accounts that there was an argument among crew members about the readings, and survivors have said the same in media accounts.

Regardless, it appears someone made a decision that the seal was good, so the crew moved to the next step: pumping seawater into the riser and taking out mud.

It was a fatal moment. The switch from mud to relatively lightweight water decreased pressure. Deep in the well, gas surged.

Originating deep in the well, the gas probably blasted through the wellhead sitting on the seafloor, perhaps overwhelming seals in that device. It surged through a blowout preventer sitting atop the wellhead, and went up the riser, expanding into multiples of its volume in the last stretch of pipe — “an exponential process once it starts,” said Tim Robertson of Nuka Research, an Alaska consultant.

Questions remain regarding when the crew detected the gas and what they did. Transocean has said the crew had almost no time.

Once the gas hit the rig, an explosion erupted. Eleven died.

Some crew members reportedly made a last-ditch effort to close the blowout preventer.

This blowout preventer has seven valves. Some clasp and unclasp the drill pipe during the course of normal work. Others close to block rising oil. And one, used only in emergencies, shears the pipe and pinches the column shut.

But the blowout preventer didn’t close. It remains unclear why.

Small mechanical glitches, such as leaking hydraulic fluids, have also raised questions.

But drilling specialists, and officials with both BP and Transocean, have said a more likely explanation is that something is jammed in the blowout preventer, or it would have responded to the multiple efforts by robotic submarines to make it work.

The force of gas bursting through the wellhead could have thrust casings, wellhead parts, drill pipe and other debris into the blowout preventer, blocking the valves. A thick well pipe joint could have also blocked it, although Transocean has said it was unlikely such a joint would be positioned in the blowout preventer at this point of the work.

It is possible, too, that the blowout preventer just wasn’t strong enough. The U.S. Minerals Management Service updated rules on the device after a 2002 study of six deepwater blowout preventers found that half the time, they couldn’t shear the pipe.

The number of possible scenarios for the accident highlights deeper issues with drilling, Patzek said. Deepwater work may, in some conditions, involve risks that no technology can anticipate, he said.

Tolerances of the seals, riser and blowout preventer, for example, appeared close to manufactured maximums and basic physical limits.

And in the deep sea, strange things happen. Gas randomly forms solids. Materials behave unpredictably. In such conditions, “we are no longer dealing with a complicated system, but with an essentially complex system,” Patzek said. “Very small factors … can create a large response.”

More to Read

Sign up for Essential California

The most important California stories and recommendations in your inbox every morning.

You may occasionally receive promotional content from the Los Angeles Times.