California’s craft rum distillers make their own rules

For centuries while the British Royal Navy vied with the Dutch and French for maritime supremacy, sailors were accorded a daily ration of high-proof rum — a tot — for their troubles. Many modern distillers have perpetuated the style of navy-strength rum, but a time-traveling mariner might scratch his head to hear craft distiller Sean Hallman describe how he makes 1893 Navy Strength Rum at Shadow Ridge Spirits Company, his Oceanside distillery.

It begins with 8-ounce cones of piloncillo sugar, about 300 of them, which Hallman tediously unwraps with help from his wife, Lisa Ireland. They dump the dense cones into a 100-gallon vessel that holds hot water, stirring the mixture with huge agitators. The process, Hallman says, “sounds like tennis shoes in a dryer.” After mixing in Grade-A molasses and backset (liquid from the previous distillation), Hallman and Ireland ferment the mixture with fruity wine yeast and send it through a copper pot still. Then they bottle it as white rum or age it in barrels that used to hold bourbon or rye for dark rum, all diluted to 90-proof. The navy-strength rum, which is loaded with vanilla and cinnamon and tastes like a high-octane oatmeal cookie, is removed from the barrels at cask strength — around 121 proof.

Much to the chagrin of traditionalists, the process doesn’t follow any particular tradition, and the date stamped on the bottle is insignificant in the history of the British tot. But it’s authentic to Hallman, a Navy veteran and the child of parents who met in the service. “Being a former naval officer myself, still working for the Department of the Navy, [the] navy-strength [style] makes sense for me,” he says.

The year 1893 is included because it’s when the U.S. Navy established the rank of chief petty officer. Hallman’s rum is an ode to his father, who retired as a master chief; family friends who were chiefs; and the petty chiefs he works alongside.

Hallman and Ireland produce a range of spirits, including whiskeys, gin and the odd experiment like an agave spirit. But the 1893 Navy Strength Rum says the most about Hallman — and the growing field of California rum distillers who like to do things their own way.

::

Although craft spirits have taken off in the last decade and interest has grown in Caribbean rum (a part of the world where specific traditions dictate distilling styles in different countries), distilling rum in the U.S. is still a challenging business, due in part to giants like Bacardi in Puerto Rico and Diageo, which owns Captain Morgan, in St. Croix. Craft distillers say generous government subsidies allow these companies to undercut competitors.

But California distillers have the advantage of being, well, in California, where experimentation is famously welcome. At San Francisco tropical bar Smuggler’s Cove, owner Martin Cate is known for rum lists with hundreds of bottles, helping inspire a more-is-more culture among amateur collectors, who are often willing to try new things and splurge on unusual bottles. (In addition, California drinkers have taken especially well to agave spirits, usually lightly aged or unaged, a good sign for distillers who haven’t been around long enough to age rums more than a few years.)

What’s more, rum is relatively unhampered by strict regulations. The federal Alcohol and Tobacco Tax and Trade Bureau requires only that rum is based on sugarcane or any sugarcane byproduct — such as molasses — and that it is distilled to under 190 proof and then diluted to no less than 80 proof. The rules for whiskey are more complex, dealing with a bevy of subcategories differentiated by ingredients, alcohol content and minimum age.

Relatively free of red tape? No need to deal with stifling local traditions? No wonder distillers up and down California have taken to rum.

That flexibility benefits small operations like Hallman’s, for whom distilling is one job among many. After eight years, he left the Navy in 2003. He managed a Home Depot and worked in distribution at Target before returning to the Navy as a civilian employee. He’s now director of training analysis at a group that helps prepare ships for deployment.

Hallman’s interest in distilling was piqued while attending an extension program on beer brewing at UC San Diego in 2014. He was close to opening a distillery with a partner who changed his mind, but Hallman and Ireland decided to continue, making their first whiskey at San Marcos distilling incubator California Spirits Company in 2017. The next year the couple moved their Shadow Ridge operation to Oceanside Distillers, where Dieter Steinmetz, a compounding pharmacist and fellow distiller, offered to share space.

With Hallman’s other two jobs — he also manages logistics for another whiskey brand — and Ireland’s work as a high school teacher, the couple make time for Shadow Ridge on weekends, producing about 400 gallons of spirits a year. The distillery’s popular bourbon, single malts and rums are priced at around $30, as are smaller releases like 1893 Navy Strength Rum, which sell out quickly. Their operation can’t compete with huge brands, so they differentiate themselves through specialty ingredients, interesting yeast strains, exacting fermentation, careful blending and constant experimentation.

Hallman, a Black distiller in a largely white industry, says there are only a few other Black distillers who are able to commit to handmade, grain-to-glass, premium spirits as he has. “Unless you’re extremely wealthy and it’s just another investment, you have to have a passion for this,” Hallman adds.

Setting up a distillery costs a lot upfront, but spirits can sit in barrels for years before turning a profit, and America’s three-tier alcohol system (producers, distributors and retailers) forces distillers to jump through hoops to get their products to drinkers. That pushes many budding entrepreneurs to source spirits from an industrial producer rather than distilling themselves. But Hallman warns that a sourced product is no different from the competitor next to it on the shelf and makes it harder to sell a brand story, which is critical to breaking through with consumers.

::

California rum distillers put their stamp on their products by opting for raw sugarcane juice or molasses, using local or global ingredients, and taking creative approaches to fermentation, distillation

,

and aging.

“They have an opinion, and they just stick to it. If that opinion is controversial or divisive, they don’t really care,” says Christ Aivaliotis, who has featured California-made rums on bottle lists and in cocktails at his bar, the Kon-Tiki, in Oakland. “That ethos is one of the things I respect.”

California craft rum has its own character; here are five to try

One of the craft rums Aivaliotis admired, white rum from Malahat Spirits Co., is made in San Diego. The distillers start with a blend of molasses and yeast from nearby White Labs (where Hallman also shops). “It was about half a year of just trying every yeast and molasses to see what flavor profile fit the best,” said Ken Lee, one of the partners at Malahat. (That attention to fermentation was inspired by local craft beer brewing culture.) Malahat also offers a citrusy ginger rum, a dry black tea rum and a floral rum aged in California Cabernet barrels.

Meanwhile, Melkon Khosrovian and Litty Mathew, husband-and-wife co-founders of L.A.’s Greenbar Distillery, also use molasses for their white and spiced rums, but they distill and blend to imitate the grassy flavors of raw sugarcane. In another break with convention, they aerate the liquid instead of barrel-aging it to soften the bite of the alcohol.

“I don’t care about tradition. We’re an L.A. company so tradition doesn’t mean anything,” Khosrovian said.

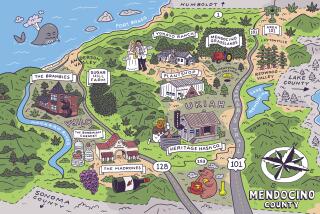

Most California distillers import molasses or evaporated cane juice, since fresh cane isn’t readily available and juice ferments quickly after harvest. But some distillers are going to great lengths to use California-grown sugarcane to make rhum agricole, a Caribbean-style spirit distilled from fermented sugarcane juice that imparts a distinct terroir.

The process can be vexing.

Earl Brown, the co-founder of Oakland’s Wright & Brown Distilling, said he tried working with sugarcane from Lee Farm in Fresno. Brown and the Lee family pressed 150 gallons of juice a few stalks at a time, breaking the small cane press but producing a rhum agricole with notes of fresh-cut grass and peaches and cream.

“The amount of work that went into it was mind-boggling,” Brown says. He hopes to buy a larger cane mill from China, although other distillers warned him that he’d have to redesign parts to meet American safety standards.

::

These are early days for the craft rum industry. For burgeoning distillers, the process can seem painfully slow: ironing out supply chains, designing quality spirits, waiting for them to age, lobbying bar owners for shelf space, lobbying distributors to sell their products and educating customers and converting skeptics through tastings.

It can go even slower at a mom-and-pop like Shadow Ridge, where Hallman and Ireland rely on their own money and have a limited number of hours each week to devote to their business. “Being a small distiller and having demand for the rum, I would love to just pump it out, but if I don’t think it’s ready and it doesn’t meet the standard, I’m not going to put it out there,” Hallman said.

Still, progress is evident at the distillery. The barrels housing spirits have grown from 5 gallons to 10, 15, 30 and, recently, 53, a standard size for much larger distilleries. Ireland and Hallman recently acquired a pilot still where they can test new recipes and accelerate product development. And in the first half of 2021, Hallman says he barreled more alcohol than in all of 2018 and 2019.

“We’re dealing with geography and we’re trying to turn it around. Our rum has its own character. Whatever happens is going to be the taste that I have,” Hallman says. “That’s what’s so great about being a craft distiller. There’s no box that holds us.”

More to Read

Eat your way across L.A.

Get our weekly Tasting Notes newsletter for reviews, news and more.

You may occasionally receive promotional content from the Los Angeles Times.