Hobie’s stand-up paddleboards helped it avoid a wipeout

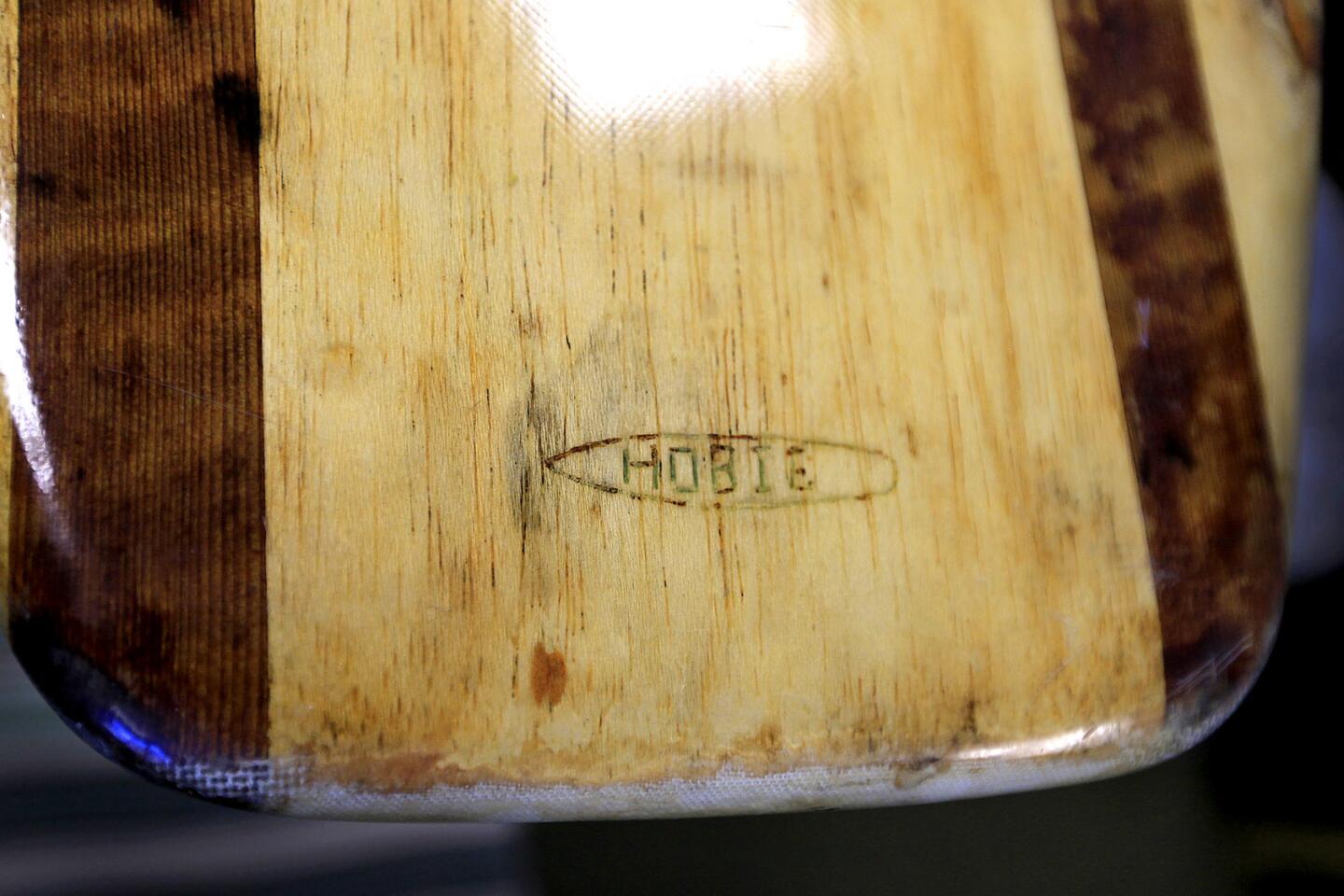

Callused hands have shaped boards for decades at the San Juan Capistrano workshop of Hobie Designs Inc., a pioneer in the quintessentially Southern California surf industry.

But increasingly those boards aren’t riding the waves.

Hobie and many other surfboard makers have found swelling sales in stand-up paddleboarding, a fast-growing sport that has flourished on calm waters.

Unlike surfing, stand-up paddleboarding doesn’t require big breakers, endless practice or the balancing skills of a tightrope walker. Paddleboarders stand on an extra-wide board and use a long oar to help them glide atop the water.

Surfing purists might scoff at the pastime, nicknamed SUP, but even hardcore veterans say that the more relaxed sport couldn’t have surfaced at a better time.

Surfboard manufacturers suffered through the 2005 loss of the major supplier of the polystyrene foam at the core of every surfboard. The industry had barely recovered when the recession came crashing down, taking sales with it.

Stand-up paddleboarding “exploded in popularity” in the last decade because of the “quick learning curve,” said former world surfing champion Shaun Tomson, now a businessman and author. “It expanded the market and gave the surfing industry a second lease on life.”

Drawn by the exercise benefits, paddleboarders spread out onto rivers, lakes and channels, like those leading to marinas. Instead of eating into surfboard sales, the hobby essentially took a form of surfing to the heartland, providing a big boost for manufacturers willing to adapt.

“Paddleboards were something of a savior for the industry,” Hobie sales director Sean Douglas said.

The Surf Industry Manufacturers Assn. didn’t begin asking its members about paddleboard sales until 2010 and found that paddleboards accounted for 22% of overall board sales of $163 million in 2013, the most recent year available.

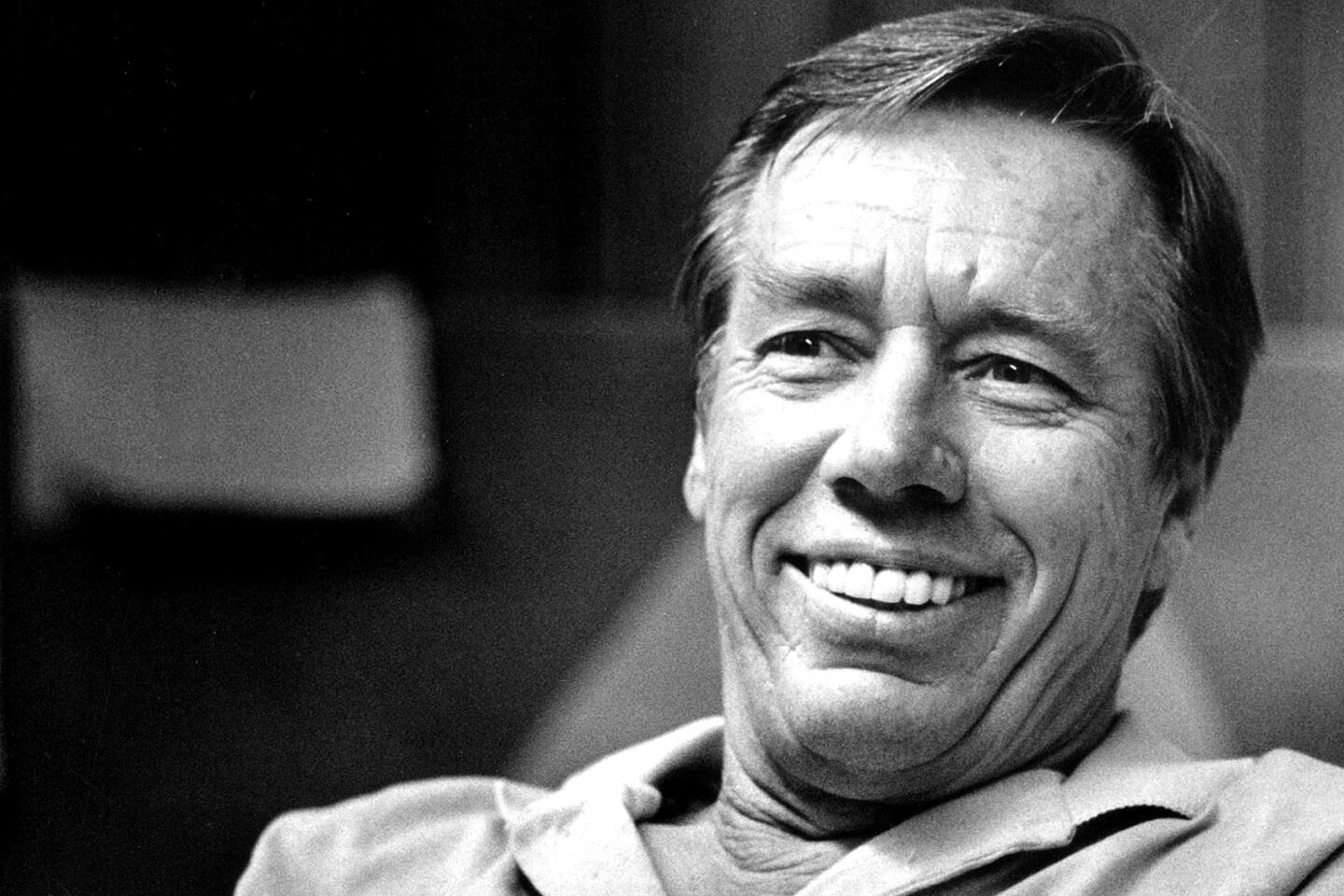

Since Hobart “Hobie” Alter started shaping surfboards out of balsa wood in his parents’ Laguna Beach garage 65 years ago, Hobie Designs has been known for developing innovative products to attract new customers.

“Hobie never stopped coming up with new ideas,” said Mark Johnson, director of sales and development for Hobie Designs. “He was always thinking about what could be the next big thing.”

That was apparent about a decade ago when the company jumped into stand-up paddleboarding. Hobie’s line was a perennial top seller, leading to various versions, including an inflatable model. But the designers weren’t happy with the oars.

In 2012, they went to the 3-D printing designers and engineers at UC Irvine. The company used the university’s expertise to come up with a better grip for the top of the oar.

“The 3-D scanning, computer-assisted design and prototype process helped us deliver this new concept as fast as we could conceive it,” said Jeff Alter, one of Alter’s three children and president of Hobie Designs.

Hobie Alter was the first to mass-produce surfboards made out of a combination of a polyurethane core, resin and fiberglass. His surfboards were only a fraction of the weight of wood boards. They were also faster and easier to control. The innovation quickly vaulted Alter to the top of the budding California surfer movement in the late 1950s and ‘60s.

Alter, who died in 2014, also conceived of a lightweight, easy-to-transport, easy-to-operate and relatively inexpensive sailing vessel he called the Hobie Cat.

Introduced in 1968, the catamaran-style Hobie Cat would become one of the world’s most popular sailing vessels. He also developed a popular paddle-powered kayak. In 1975, he sold Hobie Cat Co., which is based in Oceanside.

Alter saw no need to restrict himself to certain types of water activities, Johnson said. “Hobie’s whole philosophy was building something better for the water, and he covered just about everything.”

Hobie Designs makes or licenses the Hobie name for surfboards, paddleboards, sunglasses, women’s swim apparel and more. Hobie Designs has 12 employees, including the shapers who make the boards.

On a recent day at the Hobie workshop, Johnson shaped a surfboard, joking that “when I’m not surfing, I spend my day walking in circles” around whatever he’s making.

A surfboard starts out as a “blank,” a shell of polyurethane foam, which the shaper carves to the desired size and shape. Then the laminator, or glasser, applies liquid fiberglass, which is molded to the board like plastic cloth.

When the fiberglass is dry, a sander smooths off the board.

As an experiment, Johnson added bright orange-red dye to the fiberglass and applied it to a green-bordered board. The result resembled a surfboard-shaped slice of cantaloupe.

“Part of what keeps this fun for all of us,” Johnson said, “is that you never know how the board is going to turn out until it’s done.”

Twitter: @RonWLATimes

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.